2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃.

The strength of 2036 alloy is higher than that of 7075 alloy.

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃.

The strength of 2036 alloy is higher than that of 7075 alloy.

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

Zhongqing Metal Materials Group

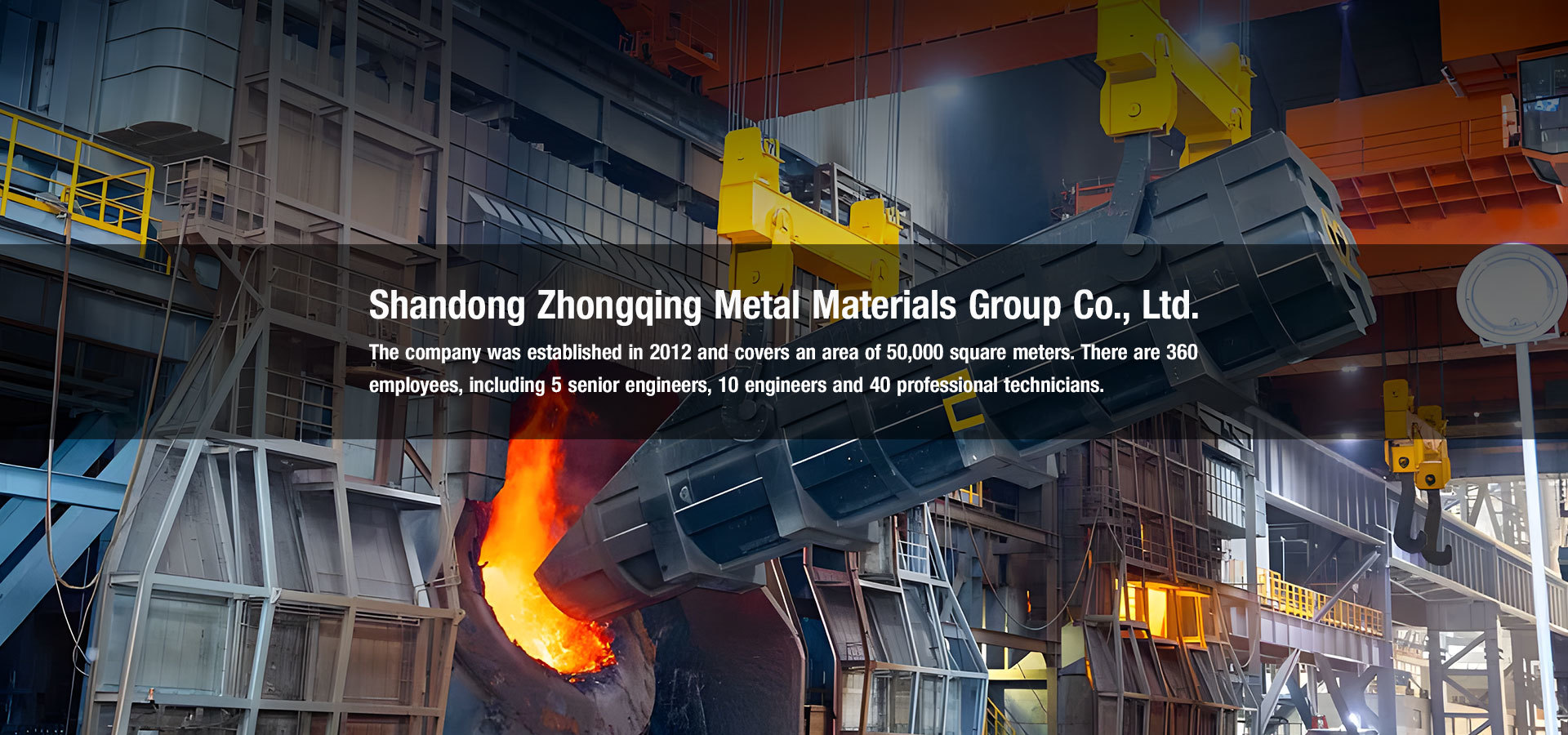

Shandong Zhongqing Metal Materials Group Co., Ltd. is a large-scale international steel production and sales enterprise integrating production, sales, processing, distribution and service.

The company was established in 2012 and covers an area of 50,000 square meters. There are 360 employees, including 5 senior engineers, 10 engineers and 40 professional technicians. There are 14 steel production lines and 10 processing equipments for processing, bending, painting, heat treatment, cutting, drilling, beveling, quenching and tempering, surface treatment, etc. Complete testing equipment and strong technical force. The annual production capacity is more than 60,000 tons.

Founded in 2012

An area of 50,000 ㎡

360 employees

14 steel production lines

WHY CHOOSE US

QUALITY ASSURANCE

We have carried out strict inspection of every part and product, trying to have no quality problems in the hands of customers.

GOOD SERVICE

Answer the customer's question within8 hours, and the service engineer will be on standby 24 hours a day.

FACTORY DIRECT SALES

Factory direct sales, no middlemen price difference.Advanced production equipment and manufacturing technology

SALES NETWORK

The products are sold to more than 20 provinces, cities and autonomous regions in China and exported to dozens of countries in Africa and Southeast Asia.

NEWS CENTER

When you choose Shandong Luban, you can trust that you are getting the best products and service in the industry.